Fresh products have by nature many different characteristics in terms of quality, shelf life, and safety. To prevent products from spoiling and to ensure that they reach the end customer in the best possible condition, product-specific conditions must be met, and an optimal environment created throughout the supply chain.

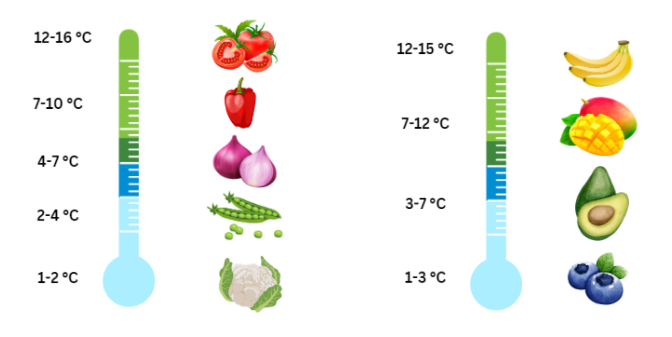

Probably one of the most important aspects of handling fresh produce is ensuring safety and hygiene. To prevent the growth of microorganisms and thus the spoilage of products, the storage room, entire operating equipment and storage personnel themselves must consistently comply with hygiene measures. The product-specific temperature and humidity conditions play an equally important role in shelf life and quality. Vegetables stored too warmly can lose up to 70% of their vitamins after just two days. Especially for fresh products with a fast metabolism, the given environmental conditions play a crucial role. The faster the metabolism, the faster the spoilage process, and the more susceptible the respective products are to pressure marks and temperature fluctuations.

Our Keelings business software gives you access to the necessary temperature data in real-time, as well as transparent traceability in terms of whereabouts, age, and cost of each pallet. A fast loading and unloading process and careful and efficient handling are of equal importance. With a simple pallet scanner and good data management, it can be ensured that perishable foods spend the shortest possible time in the warehouse and arrive at the point of sale on time and in the best condition possible.

Our ERP system was developed from the industry for the industry and helps you to master the many challenges of the fresh produce industry. Benefit from a century of experience as a family business in the fresh produce industry. Stay in control of your supply chain. For questions, we are at your disposal at any time.